Resilient modulus is a fundamental property of materials that measures their ability to deform and recover under stress. It is a key parameter in the design and analysis of pavements, as it helps engineers determine the structural capacity and long-term performance of roadways. However, the resilient modulus of a material is not a constant value, but rather a function of stress.

Stress plays a crucial role in determining the resilient modulus of a material. As stress is applied to a material, it causes the material to deform. The resilient modulus measures the material’s ability to recover its original shape and dimensions after the stress is removed. The relationship between stress and resilient modulus is complex and depends on various factors.

There are several key factors that influence the stress dependent resilient modulus of a material. One of the most important factors is the type of material itself. Different materials, such as soils, aggregates, and asphalt, have different resilient modulus values and behave differently under stress. The composition, gradation, and mechanical properties of the material all affect its resilient modulus.

Another important factor is the applied stress level. As the stress level increases, the resilient modulus generally decreases. This is because higher stress levels cause more deformation in the material, reducing its ability to recover. The relationship between stress and resilient modulus can be described by mathematical models, such as the power law or the sigmoidal model.

Understanding the stress dependent resilient modulus is crucial for the design and analysis of pavements. By accurately predicting the resilient modulus of different materials under different stress levels, engineers can ensure the structural integrity and long-term performance of roadways. This knowledge can help optimize pavement designs, improve pavement performance, and ultimately enhance the safety and efficiency of transportation systems.

Overview of the Stress Dependent Resilient Modulus

The stress dependent resilient modulus is a key factor in understanding the behavior of materials under different stress conditions. It refers to the ability of a material to recover its original shape and dimensions after being subjected to stress. The resilient modulus is an important parameter in the design and analysis of pavement structures, as it provides valuable information about the material’s ability to withstand repeated loading and maintain its structural integrity.

The stress dependent resilient modulus is influenced by various factors, including the type and composition of the material, the stress level applied, and the loading frequency. Different materials exhibit different resilient modulus values, with some materials being more resilient than others. The resilient modulus can also change over time, as materials undergo aging and degradation.

Understanding the stress dependent resilient modulus is crucial for predicting the performance and lifespan of pavement structures. By studying how the resilient modulus changes under different stress conditions, engineers can make informed decisions about material selection, design specifications, and maintenance strategies. This knowledge can help optimize pavement designs and ensure their long-term durability and performance.

Applications of the stress dependent resilient modulus include pavement design and analysis, quality control of construction materials, and pavement performance prediction. By accurately measuring and predicting the resilient modulus of materials, engineers can ensure the safe and efficient operation of transportation infrastructures.

Importance of Understanding the Stress Dependent Resilient Modulus

The modulus is a fundamental property that characterizes the behavior of materials under stress. It provides insights into how a material responds to external forces and how it can withstand deformation without permanent damage. In the field of civil engineering, understanding the stress dependent resilient modulus is of utmost importance for designing and constructing durable and reliable infrastructure.

The resilient modulus is a measure of a material’s ability to recover its original shape after being subjected to repeated loading and unloading cycles. It represents the stiffness and elasticity of the material and is a key parameter in pavement design and analysis. The stress dependent nature of the resilient modulus refers to its variation with applied stress levels.

By understanding the stress dependent resilient modulus, engineers can accurately predict the performance of various materials under different stress conditions. This knowledge allows for the optimization of pavement designs, leading to longer-lasting and more cost-effective infrastructure. It also enables the selection of appropriate materials for specific applications, ensuring that they can withstand the anticipated traffic and environmental loads.

Furthermore, the stress dependent resilient modulus provides valuable insights into the behavior of materials under extreme conditions, such as heavy traffic or harsh environmental factors. By studying how the modulus changes with stress, engineers can identify potential failure mechanisms and develop strategies to mitigate them. This proactive approach helps prevent premature pavement distress and reduces the need for costly repairs and maintenance.

In conclusion, understanding the stress dependent resilient modulus is crucial for ensuring the longevity and performance of infrastructure. It allows engineers to make informed decisions regarding pavement design, material selection, and maintenance strategies. By considering the stress-dependent behavior of materials, engineers can optimize the performance and durability of infrastructure, ultimately leading to safer and more sustainable transportation systems.

Key Factors Affecting the Stress Dependent Resilient Modulus

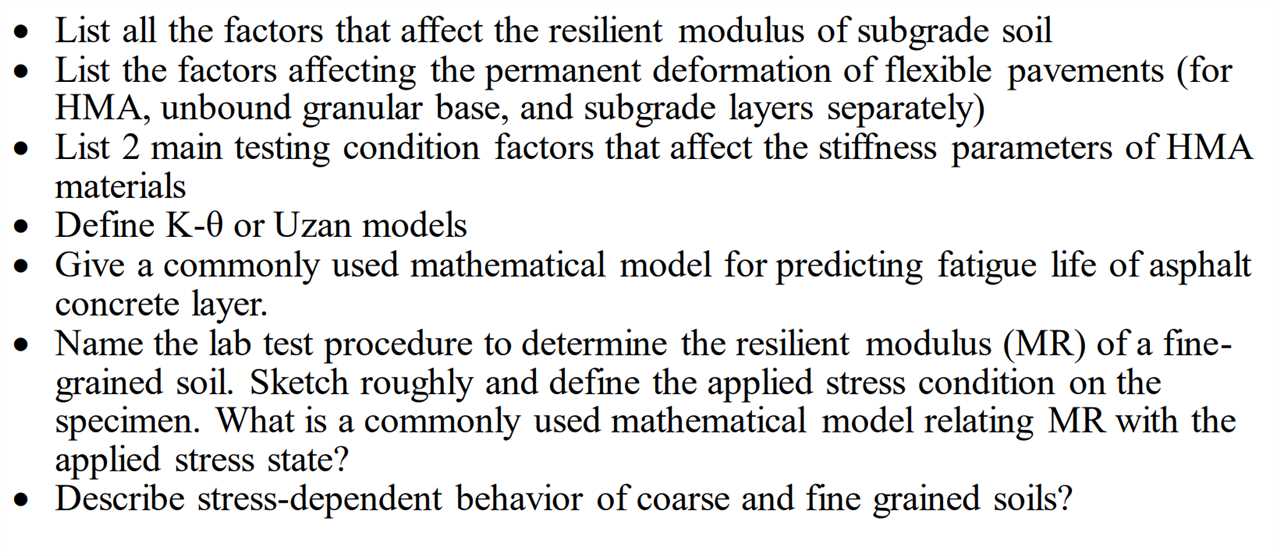

The stress dependent resilient modulus is an important parameter in the design and analysis of pavement structures. It represents the ability of a material to withstand repeated loading and recover to its original shape. Understanding the key factors that affect the stress dependent resilient modulus is crucial for ensuring the long-term performance and durability of pavements.

One key factor that affects the stress dependent resilient modulus is the type of material used. Different materials have different resilient modulus values, which can vary significantly depending on their composition and properties. For example, asphalt concrete typically has a lower resilient modulus compared to cement concrete due to its higher flexibility and deformability.

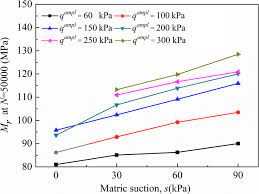

Another important factor is the stress level applied to the material. The stress dependent resilient modulus is typically determined at a range of stress levels to capture the material’s response under different loading conditions. Higher stress levels can result in a decrease in the resilient modulus, indicating a decrease in the material’s ability to recover its shape.

The temperature also plays a significant role in the stress dependent resilient modulus. As the temperature increases, the resilient modulus of materials generally decreases. This is due to the increased mobility of molecules, leading to greater deformation and reduced stiffness. Temperature changes can have a significant impact on the long-term performance of pavements, especially in regions with extreme temperature variations.

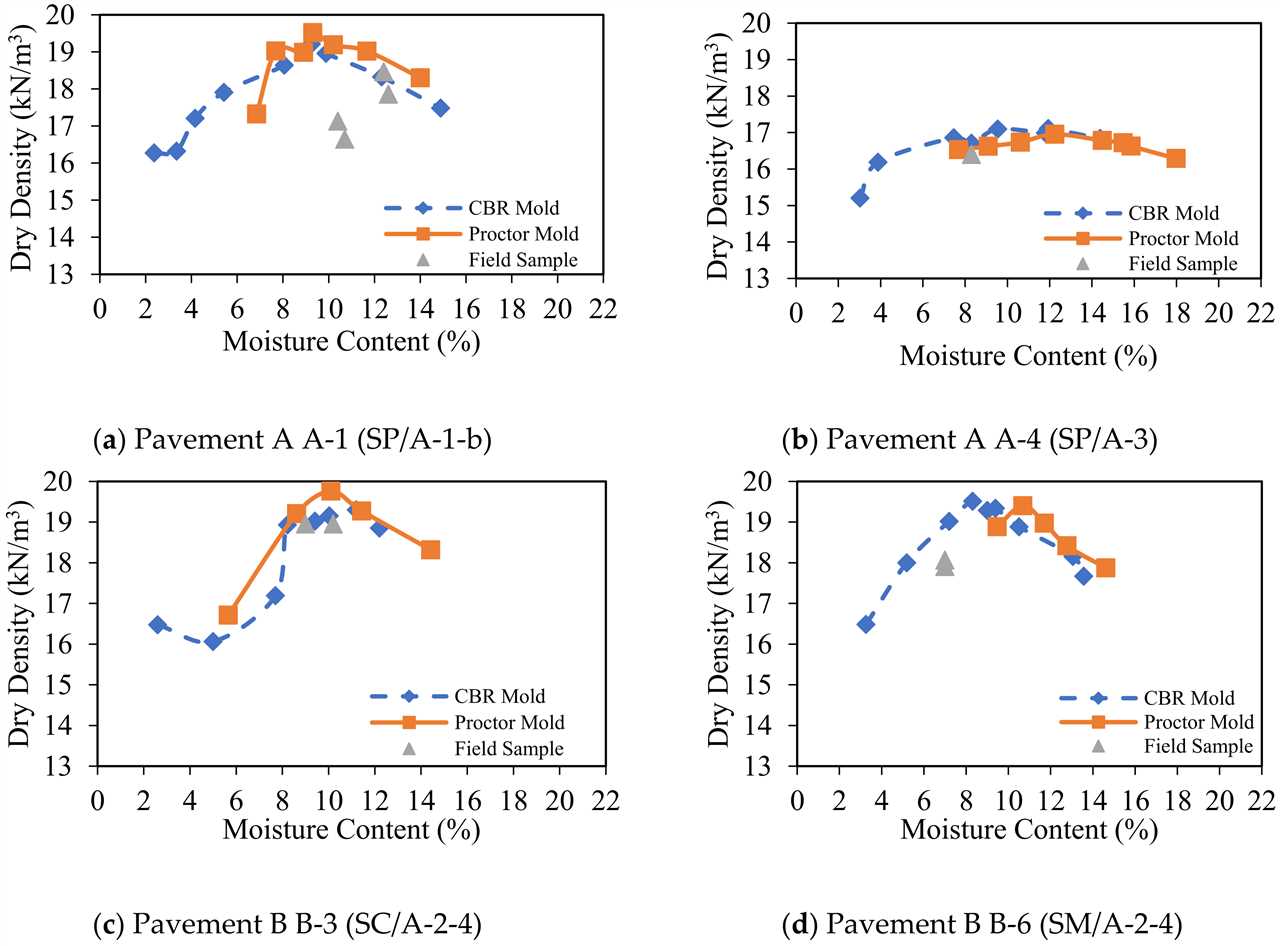

The moisture content of the material is another critical factor affecting the stress dependent resilient modulus. Moisture can alter the internal structure of the material, leading to changes in its mechanical properties. Increased moisture content can result in a decrease in the resilient modulus, as it reduces the material’s ability to resist deformation and recover its shape.

Overall, the stress dependent resilient modulus is influenced by various factors, including the type of material, stress level, temperature, and moisture content. Understanding these key factors is essential for accurately predicting the performance and durability of pavements, and for designing resilient and long-lasting pavement structures.

Soil Type and Composition

The resilient modulus of a soil is highly dependent on its type and composition. Different soil types exhibit different behaviors under stress, which can greatly affect their resilient modulus values.

For example, cohesive soils such as clay tend to have higher resilient modulus values compared to granular soils like sand. This is because cohesive soils have a higher degree of interparticle bonding, which allows them to better withstand stress and deformation.

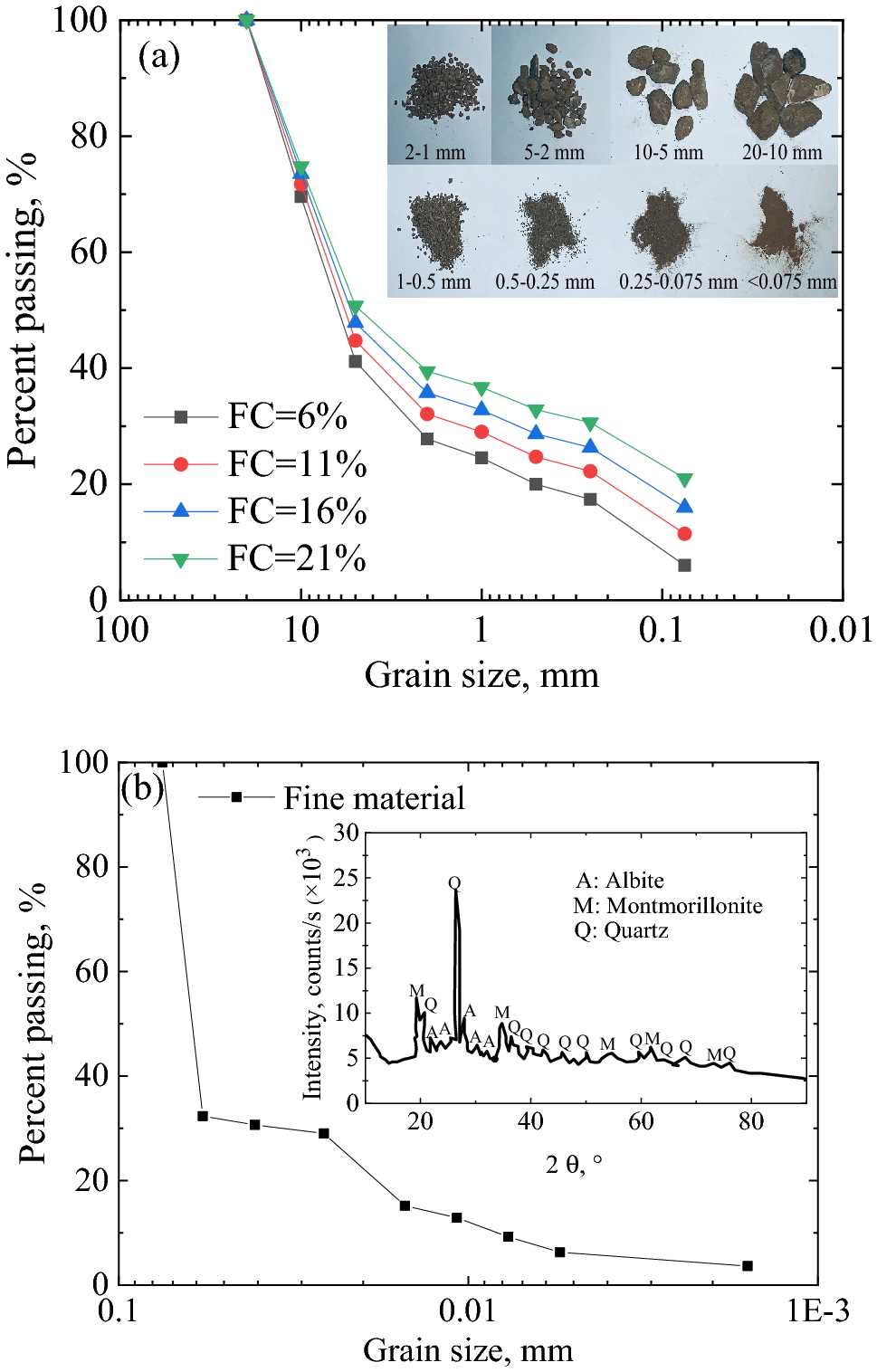

In addition to soil type, the composition of the soil also plays a significant role in determining its resilient modulus. The presence of organic matter, moisture content, and particle size distribution can all influence the resilient modulus of a soil.

Soils with a higher organic matter content generally have lower resilient modulus values due to their increased compressibility and lower strength. Similarly, soils with a high moisture content tend to exhibit lower resilient modulus values because the excess water reduces the interparticle bonding and increases the soil’s compressibility.

The particle size distribution of a soil also affects its resilient modulus. Soils with a wide range of particle sizes, such as well-graded soils, tend to have higher resilient modulus values compared to soils with a narrow particle size distribution. This is because the presence of different-sized particles allows for better interlocking and load transfer between particles, resulting in higher stiffness and strength.

In summary, the resilient modulus of a soil is influenced by its type and composition. Understanding these factors is crucial for accurately predicting the behavior of soils under stress and designing resilient structures that can withstand the anticipated loads.

Moisture Content and Saturation Level

The stress-dependent resilient modulus of a material is greatly influenced by its moisture content and saturation level. Moisture content refers to the amount of water present in the material, while saturation level indicates the degree to which the material is filled with water.

When a material is subjected to stress, its resilient modulus is affected by the presence of moisture. Moisture content can alter the stiffness and strength of the material, leading to changes in its ability to withstand stress and deformation. A higher moisture content generally results in a lower resilient modulus, as the water acts as a lubricant, reducing the friction between particles and allowing for greater deformation.

Similarly, the saturation level of a material can have a significant impact on its stress-dependent resilient modulus. A fully saturated material, where all void spaces are filled with water, tends to have a lower resilient modulus compared to a partially saturated or dry material. This is because the water in the void spaces reduces the contact between particles, resulting in a weaker overall structure.

It is important to consider the moisture content and saturation level of a material when assessing its stress-dependent resilient modulus. These factors can provide valuable insights into the behavior and performance of the material under different stress conditions. By understanding the influence of moisture, engineers and researchers can make more informed decisions regarding the design and construction of resilient structures.

Confining Pressure and Stress Level

The resilient modulus of a material is dependent on various factors, including the confining pressure and stress level it experiences. Confining pressure refers to the lateral pressure applied to a material, which can significantly affect its mechanical behavior.

When a material is subjected to higher confining pressures, it experiences increased resistance to deformation. This is because the confining pressure helps to confine the particles within the material, reducing their ability to move and resulting in a higher resilient modulus.

On the other hand, the stress level applied to a material also plays a crucial role in determining its resilient modulus. Stress level refers to the magnitude of stress applied to a material, which can be measured in terms of load or strain.

Higher stress levels generally result in a lower resilient modulus, as the material undergoes more severe deformations and experiences greater strain. Conversely, lower stress levels lead to a higher resilient modulus, indicating that the material is more resistant to deformation.

Understanding the relationship between confining pressure and stress level is essential for predicting the behavior of materials under different loading conditions. By considering these key factors, engineers and researchers can design resilient structures and pavements that can withstand varying levels of stress and pressure.

Applications of the Stress Dependent Resilient Modulus

The stress dependent resilient modulus is a key factor in various engineering applications. Its ability to predict the behavior of pavement materials under different stress conditions makes it a valuable tool in pavement design and analysis.

One of the main applications of the stress dependent resilient modulus is in the design of flexible pavements. By understanding how the modulus changes with stress, engineers can accurately predict the performance of the pavement under different traffic loads. This information helps in selecting the appropriate materials and thicknesses for the pavement layers, ensuring its long-term durability and performance.

Another application of the stress dependent resilient modulus is in the evaluation of pavement performance. By measuring the modulus at different stress levels, engineers can assess the structural condition of the pavement and identify potential areas of distress. This information is crucial for maintenance and rehabilitation planning, as it helps prioritize the areas that require immediate attention.

The stress dependent resilient modulus is also used in the development of pavement design guidelines and specifications. By incorporating the modulus values into design equations, engineers can ensure that the pavement will meet the desired performance criteria. This helps in optimizing the use of materials and resources, leading to more cost-effective and sustainable pavement designs.

Furthermore, the stress dependent resilient modulus plays a vital role in the characterization of pavement materials. By measuring the modulus at various stress levels, engineers can assess the stiffness and strength properties of the materials. This information is crucial for material selection and quality control, ensuring that only the best materials are used in pavement construction.

| Applications | Benefits |

|---|---|

| Pavement design | Accurate prediction of pavement performance |

| Pavement evaluation | Identification of potential distress areas |

| Development of design guidelines | Optimization of pavement designs |

| Material characterization | Assessment of stiffness and strength properties |

In conclusion, the stress dependent resilient modulus is a valuable tool in pavement engineering. Its applications range from pavement design and evaluation to the development of design guidelines and material characterization. By understanding the modulus’s behavior under different stress conditions, engineers can make informed decisions that lead to more durable, cost-effective, and sustainable pavements.

Pavement Design and Evaluation

Pavement design and evaluation play a crucial role in ensuring the long-term performance and durability of road infrastructure. Resilient modulus is a key factor that is used to assess the structural capacity and response of pavement materials under different stress conditions.

The resilient modulus is a measure of the stiffness and ability of a pavement material to recover its original shape and support traffic loads after being subjected to stress. It is an important parameter in pavement design as it helps engineers to determine the appropriate thickness and composition of the pavement layers to withstand the anticipated traffic loads and environmental conditions.

Stress-dependent resilient modulus testing is conducted to evaluate the performance of pavement materials under different stress levels. By subjecting specimens to varying stress conditions, engineers can obtain valuable data on the resilient modulus values at different stress levels, which can then be used to predict the long-term performance and behavior of the pavement.

The results from stress-dependent resilient modulus testing can be used in pavement design and evaluation to optimize the design of new pavements and assess the structural capacity of existing pavements. By understanding how the resilient modulus of pavement materials changes with stress, engineers can make informed decisions on the selection of materials and the design of pavement structures to ensure their long-term performance and durability.

In conclusion, pavement design and evaluation are critical aspects of road infrastructure development. The resilient modulus is an important parameter that helps engineers assess the structural capacity and response of pavement materials under different stress conditions. By conducting stress-dependent resilient modulus testing, engineers can obtain valuable data to optimize pavement design and evaluate the performance of existing pavements.

Geotechnical Engineering and Soil Stabilization

Geotechnical engineering plays a crucial role in ensuring the stability and durability of structures built on soil. The behavior of soil under different loading conditions, including stress and strain, is a key factor in determining the performance of these structures.

One important parameter used in geotechnical engineering is the modulus of resilience, which is a measure of a material’s ability to absorb and dissipate energy under stress. The resilient modulus of soil is particularly important in understanding its behavior under cyclic loading, such as that experienced by pavements and other transportation infrastructure.

Soil stabilization techniques are often employed to improve the mechanical properties of soil and enhance its load-bearing capacity. These techniques involve the addition of stabilizing agents, such as cement, lime, or fly ash, to the soil to increase its strength and stability. The use of these stabilizing agents can also enhance the resilient modulus of the soil, making it more resistant to deformation and better able to withstand repeated loading cycles.

Stabilization techniques can be used in a variety of geotechnical engineering applications, including road construction, embankment construction, and foundation design. By improving the resilient modulus of the soil, these techniques can help to reduce the risk of settlement, rutting, and other forms of distress that can occur due to repeated loading.

In conclusion, geotechnical engineering and soil stabilization are closely interconnected. The understanding of the stress-dependent resilient modulus is crucial in designing and constructing structures that can withstand the demands of their environment. By employing soil stabilization techniques, engineers can enhance the resilient modulus of soil, improving its performance and ensuring the long-term stability of infrastructure projects.

I am Patrina de Silva, a psychologist and mental health blogger in Sri Lanka. After obtaining psychology degrees from the University of Colombo and Monash University, I returned home to work as a counselor while also starting the popular blog “Pressy but Happy” to provide advice on psychological issues. Over the past decade, my empathetic articles have made my blog a leading mental health resource in the country. In addition to writing, I maintain a private therapy practice, frequently volunteer counseling time, and conduct seminars, driven by my passion for destigmatizing mental illness and educating the public on the mind-body connection. I strive to be an influential voice in my field through my compassionate approach.